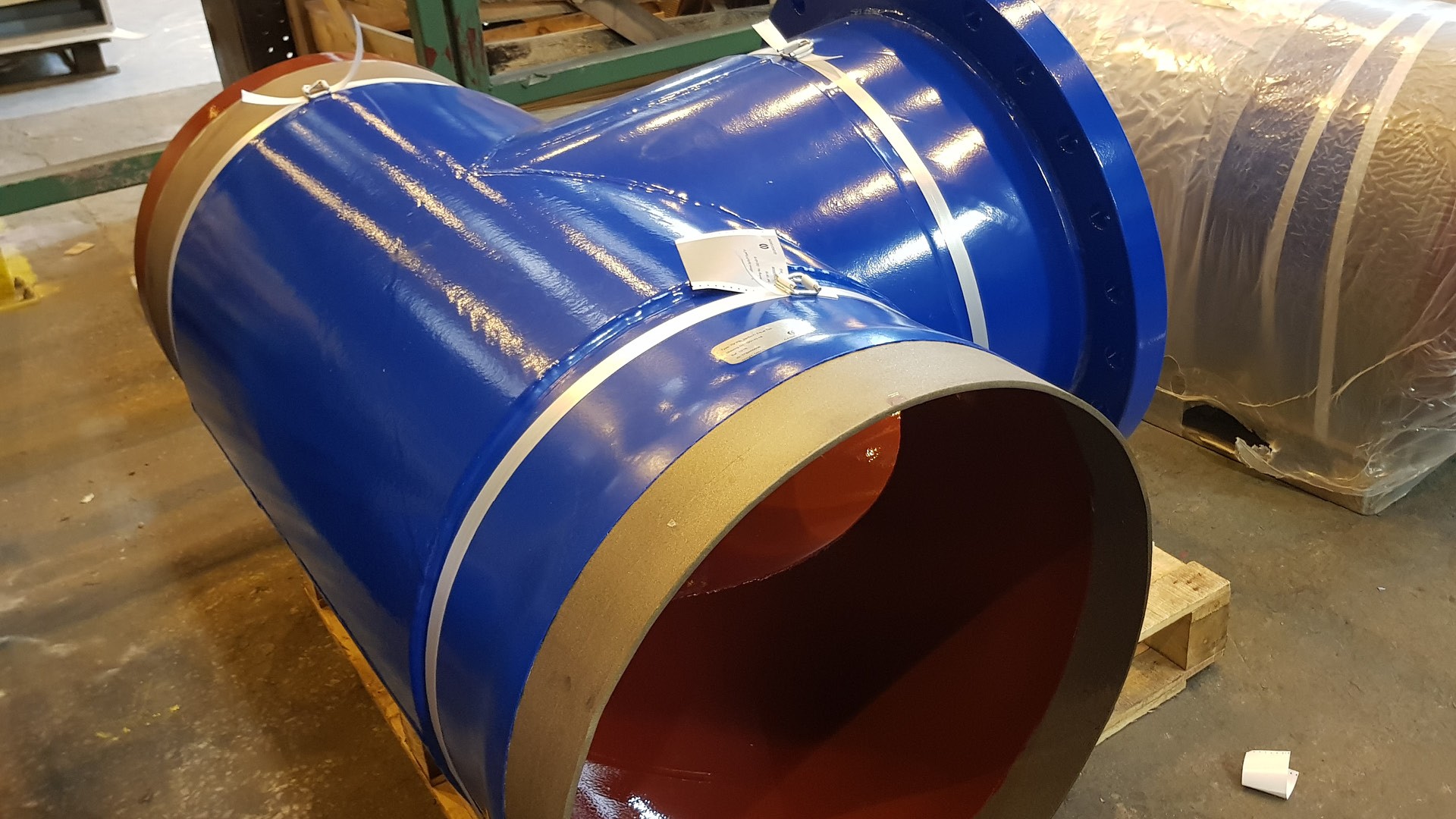

Mild steel pipework fabrications can be offered in a variety of DWI & WRAS approved coatings including

- Resicoat R4-FB HKC04R

- Eurokote Thixo 468

- Scotchkote 206N

Akzo Nobel Resicoat is the preferred FBE coating option on mild steel and holds a comprehensive range of approvals combined with a worldwide track record for its aesthetic finish, reliability & asset life.

Resicoat can be applied to external and internal surfaces of pipes and fittings and exceeds all industry pipe coating standards. We also have approval from the Drinking Water Inspectorate (DWI) to provide flanged and screwed stainless steel pipework and fittings of all diameters and grades. Our first-class pipework is also used by many other industries, including wastewater, oil, gas and petro chemical.

George Green pride themselves on their ability to meet tight and difficult delivery programmes, & are contactable 24 hours a day, 7 days a week via our Email Portal where any alerts are viewed by our Sales Team In/Out of Office Hours with response times that are second to none, and we will ensure we find solutions for our growing Customer base.

Our services

We manufacture and supply fabricated carbon and stainless steel pipework to the UK water sector. We offer bespoke pipe fittings and specials where we value engineer your designs and drawings, likewise we can offer alternative solutions to ductile iron pipework designs.

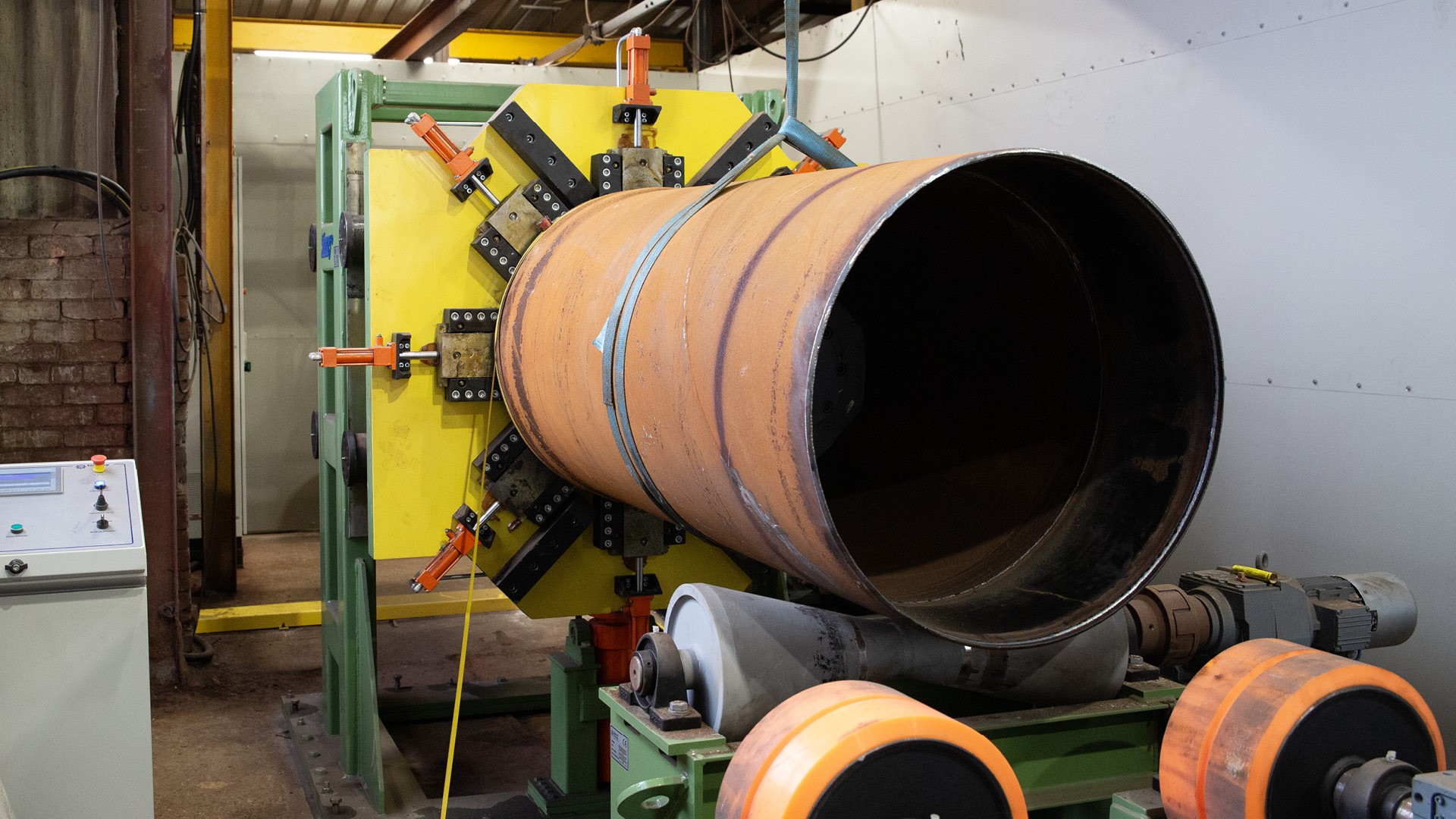

Submerged arc welding service that allows us to produce welded pipework up to 3,000mm in diameter, Maximum of five tonnes in weight, and six metres in length

Refurbishment and renewal of boreholes, surface pipework, rising main

Bespoke fabricated fittings, including Bends, Duckfoot Bends, Lobster Backs (Segmental),

Equal Tees, Reducing Tees, Concentric /Eccentric Reducers, Manifolds, Bellmouths

Larger size flanges are available on request. If you require any non-standard flanges, we have in house profile & machining capabilities to make these to order.

Spigot, socket & butt-welded pipework joints are suitable where man entry into the pipe is suitable.

Insulation Sleeve – We also offer a Spigot/socket welded joint having a thermal sleeve located into the Spigot end of the pipe or fitting. This enables the joint to be welded externally without the internal lining being damaged by the heat of the welding process. This type of joint can be offered over our diameter range and employed irrespective of the pipe being man entry or not. The decision as to if the pipe is man entry or otherwise, is of course, determined by the Client and current regulations. George Green is the leading supplier in the UK and Ireland, of this type of joint.

Mechanical Joints, couplings and flange adaptors, complete with bolt and gasket sets can be supplied to offer customers the complete package.

E-Joints

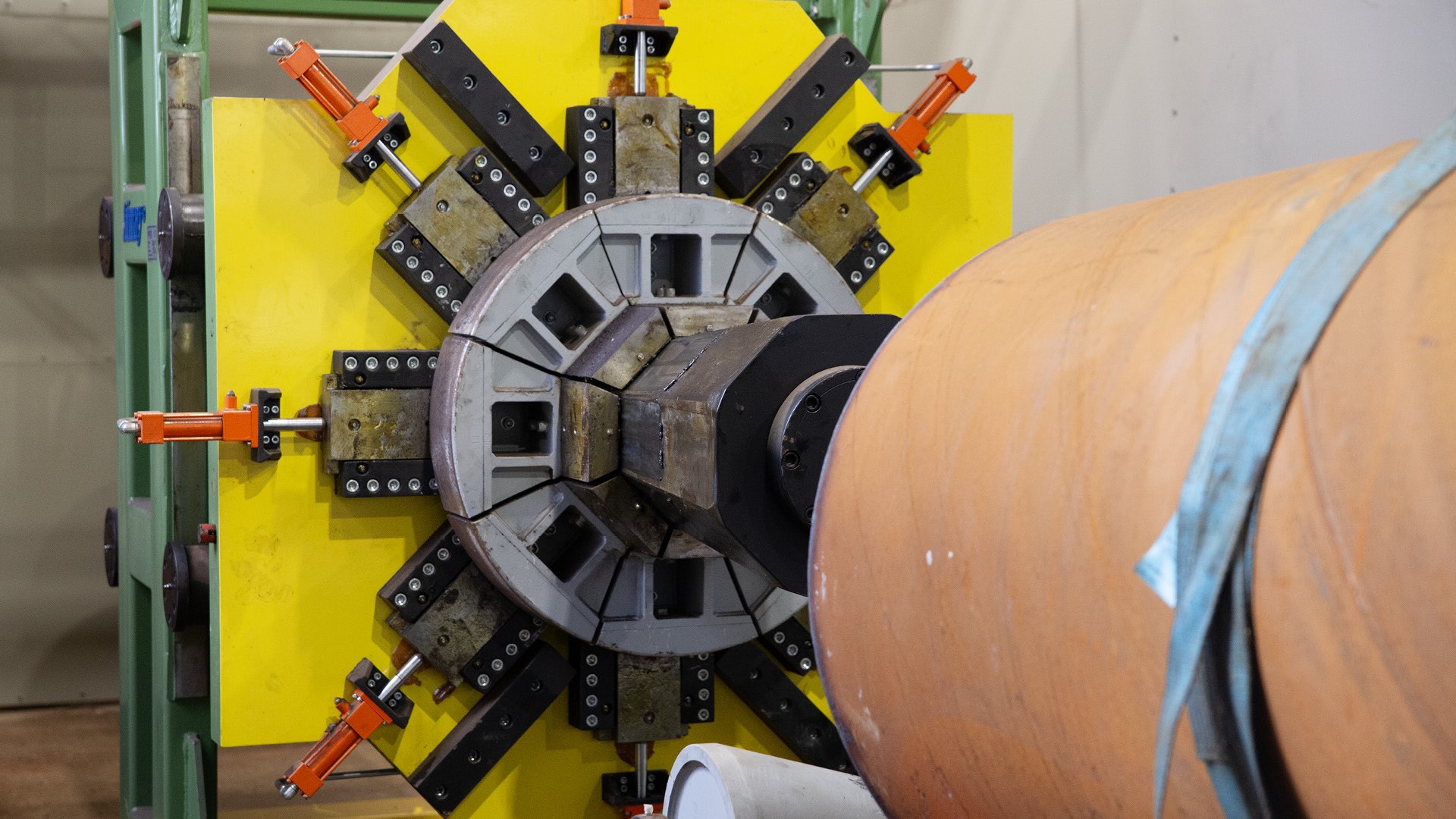

George Green is now very proud to announce that after much research, development and investment the organisation has over the last year or so been manufacturing and supplying pipes and fittings with the bona fide E-joint . This joint is produced in house at our Keighley manufacturing site and is supplied over our diameter range. These pipes and fittings are now installed on a number of projects around the UK. We have been able to do this by committing and investing time and money in the most up to date computerised equipment and professionally trained operatives ensure we produce a high-quality product.

Beneficially for the Installer saving time, and remedial costs the E-joint is a mechanism that allows the Steel Pipe/Fitting to be welded together externally only and with the major advantage that the welding process does not damage the internal lining thus mitigating the need to enter the pipe, irrespective of the pipe being man entry or not. This is achieved by the creation of an air chamber at the spigot end of the pipe or fitting, This is achieved by an internal sleeve being welded into place using our duel headed welding console.

In addition, George Green has made further investment to enable them to have the ability to expand a pipe end to form a socket to high tolerances. This is achieved using a computer controlled hydraulic expansion machine. All functions of the expander equipment are designed to be controlled manually on the operator control panel, furthermore they can be run automatically under the control of the operator.

On site the socket end then works in tandem with the spigot/E-joint end, so that the male spigot end is entered into the female socket end, and a field weld is performed on the external of the pipe joint only.

Key services

- Manufacture & supply to UK water sector

- Submerged arc welding

- Refurbishment and renewals

- Bespoke fabricated fittings

- Bends, duckfoot bends & lobster backs

- Equal tees

- Reducing tees

- Concentric/eccentric reducers

- Manifolds

- Bellmouths

- Larger flange sizes

- Spigot, socket & butt-welded joints

- Insulation sleeves

- Mechanical joints

- Couplings

- Flange adaptors